LE JARDIN DU SOLEIL VERT

Project management & constructor: FS TECHNOLOGIES and MANAGEMENT

Concept: HALUCINARIUM | Triaj Creativ

Beneficiary: VEOLIA / APA NOVA Romania

Location: Glina Wastewater Treatment Plant

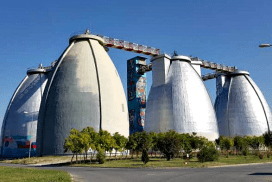

The Glina Wastewater Treatment Plant is equipped with 5 sludge fermentation tanks, with a pear-shaped structure and a capacity of 8,000 m3. Built in the 1990s, their metal facades (galvanized sheet metal) have been damaged by exposure to extreme weather conditions, pollution and gas emissions.

- Rehabilitation and corrosion protection - 5 digesters

- Metal structure with a height of 36 meters and 8000 cubic meters

- Works carried out under special conditions, respecting antiex conditions (explosion hazard area)

- Waiting time between layers: 45 min - 4h

- UV resistant protection, excellent chemical resistance and durable flexibility

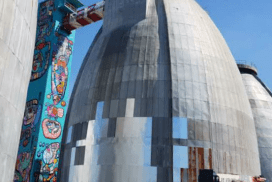

- After applying the protection layers, the decorative painting was done by hand, with a brush, from nacelles; colours were pigmented on site

- 3 nacelles were used: 2 of 45 meters high and one of 20 meters high.

Visual inspection of the surface revealed that the board is heavily corroded: brown rust and white rust (salts). A first water wash with 500 – 1000 bar pressure revealed new whitish white rust stains, with a rough irregular appearance to the touch. These were randomly formed on the entire surface of the digesters and could not be removed by simple pressure washing. Being an anti-ex area, it was not possible to use tools/equipment that produce sparks on impact, implying other mechanical cleaning methods, including brushing with wire brushes or grinding. Innovative solution: application of a brown and white rust neutralizing product, Eco cleaner (100% biodegradable product) with a thickness of 500 microns, left to act for a minimum of 12 hours. Removal of the resulting layer was achieved by additional washing with water at 500 – 1000 bar pressure.

Following the dismantling of the severely damaged plates, the phenomenon of “welding/bonding” between the metal plate, the screws and the supporting structure of the facade was observed. In some cases, part of the supporting structure was replaced, including portions with reduced thickness due to corrosion. The joining was carried out by means specific to the area. Heavily corroded, perforated or thinned metal plates were dismantled piece by piece, then new, custom-made metal plates were hand-made for replacement.

Specially designed protection for this application: 3-layer protection system with moisture hardening:

- zinc-based primer;

- intermediate layer of myo metallic fibre mastic;

- final layer – topcoat – flexible, with excellent chemical and UV resistance

ADVANTAGES of this technical solution: Protective system can be applied in conditions of 6% to 99% relative humidity; no restrictions related to substrate humidity or condensation; moisture resistance only 30 minutes after application, single component: no reaction time, no mixing errors, no excessive losses, simple to use, time saving per overall project; airless spray application.