CONTEXT

Bucharest is facing major challenges in managing its sewage infrastructure, due to ageing networks and the increasing demands generated by population growth and real estate developments. In addition, climate change is generating extreme weather events, putting additional pressure on the system.

The sewerage network on Str. Moise Nicoară shows a high degree of wear and tear, the existing pipe being clogged. This significantly reduces its performance and efficiency. The rehabilitation project aims to solve the problem by using trenchless technology: static bursting of the damaged pipe and the introduction of PP-H AlphaPlus® – homopolymeric polypropylene (SIMONA patented technology) pipe modules with integrated connection with tensile protection and double EPDM wedge seal. This method ensures a watertight pipe with enhanced hydraulic performance, thus contributing to increased wastewater transport capacity and reduced risk of blockages.

Through the use of state-of-the-art equipment and high quality materials, the project will contribute to increasing the lifespan of the rehabilitated infrastructure, reducing maintenance costs and improving the overall performance of the sewage system. In addition, the technology minimizes disruption to the community and reduces environmental impact.

PROJECT OVERVIEW

- Purpose: Renewal of a clogged pipe with minimal impact on residents for optimal safe operation.

- Method: Static bursting of the clogged pipe and insertion of PP-H AlphaPlus® AlphaPlus® PP-H pipe segments, resulting in a watertight pipe with increased hydraulic performance.

- Location: Bucharest, Moise Nicoară Street

- Beneficiary: Drinking water supply and wastewater treatment operator – Bucharest

- General Contractor: AVIProd

- Specialized contractor: Conscut Construcții

- Designer: Apa Nova București

- Equipment and piping supplier: FS Technologies and Management

THE INITIAL SITUATION

Area with major intervention difficulties (Moise Nicoară Street)

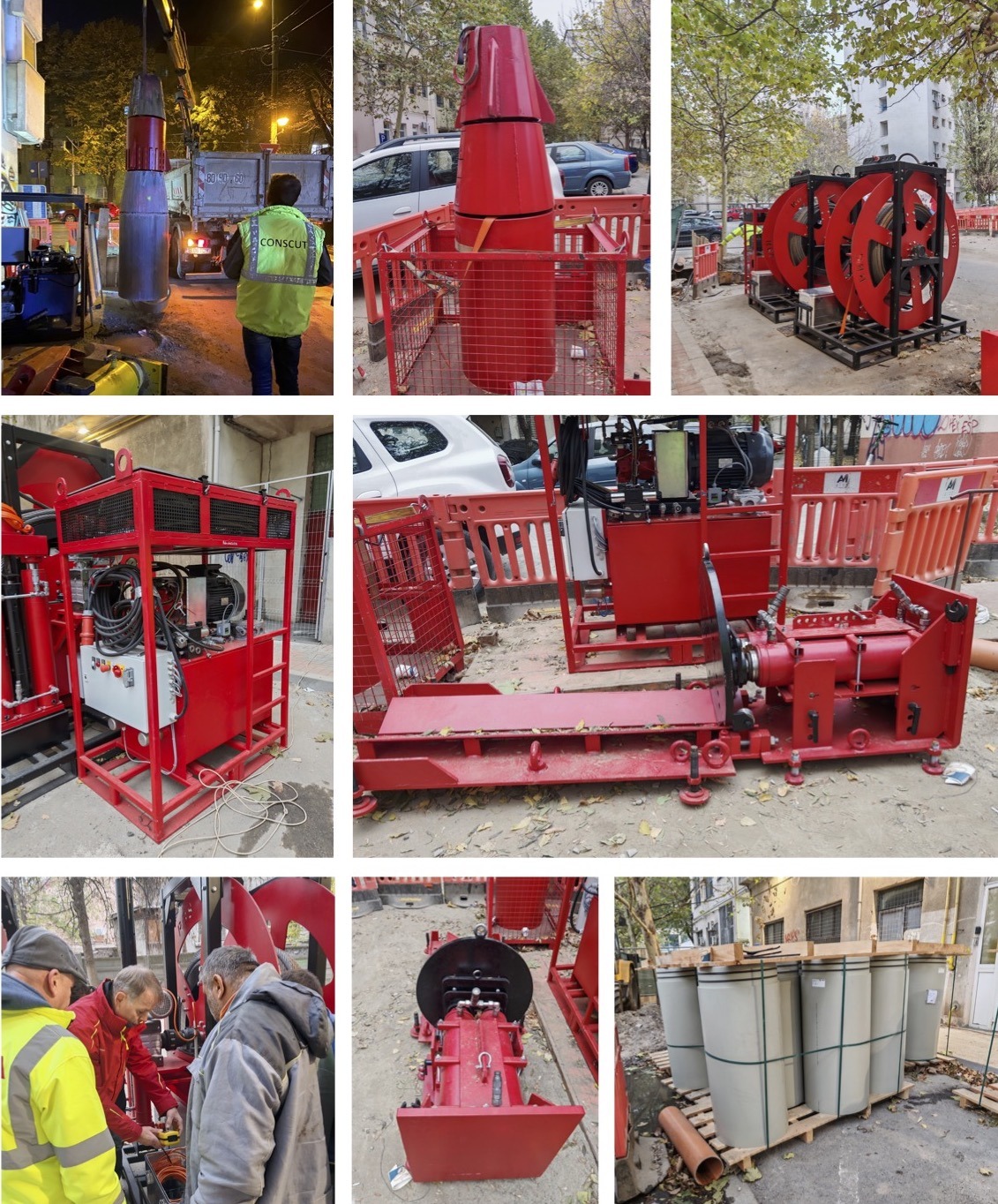

🔹 The section of sewer (DN 500, concrete) is located in an area with difficult access, next to the foundation of a 10-story apartment building and platan trees with extensive roots (which, over time, have collected gravel, further compacting the soil).

🔹 Advanced clogging, impeding video inspection

🔹 Massive concrete encasement around the old pipe (probably poured when the old pipe was put in place to seal off two pipe segments that had differences in the centerline).

🔹 Compacted soil, increasing friction forces during intervention

SOLUTION: NO-DIG REHABILITATION

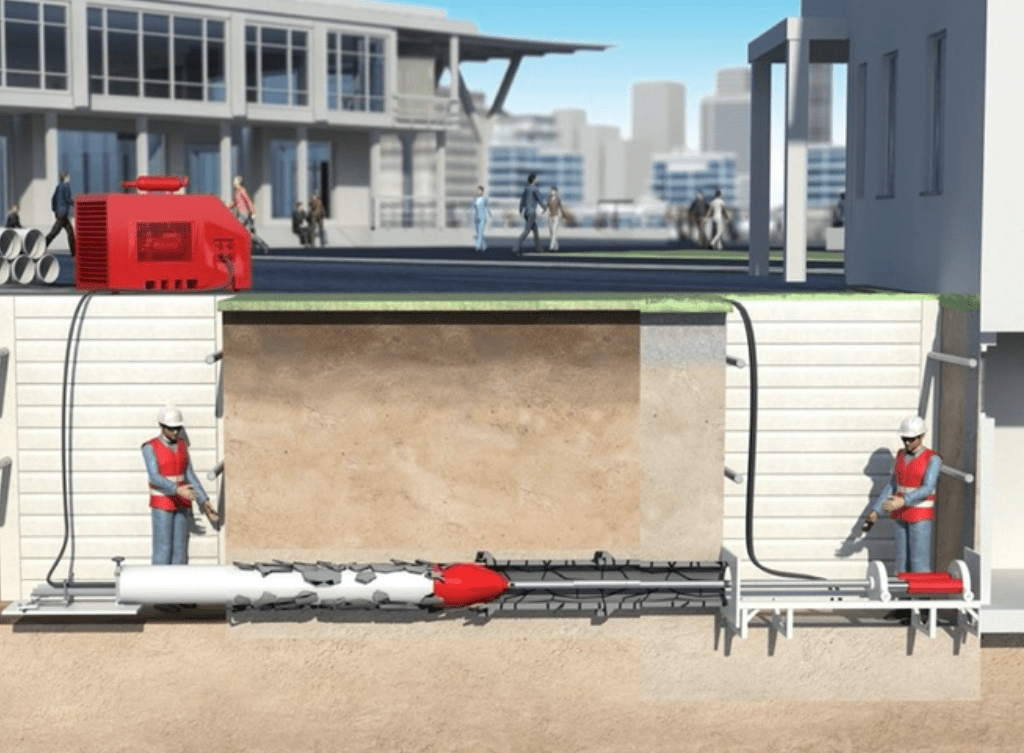

The following trenchless technology was used to remedy the situation:

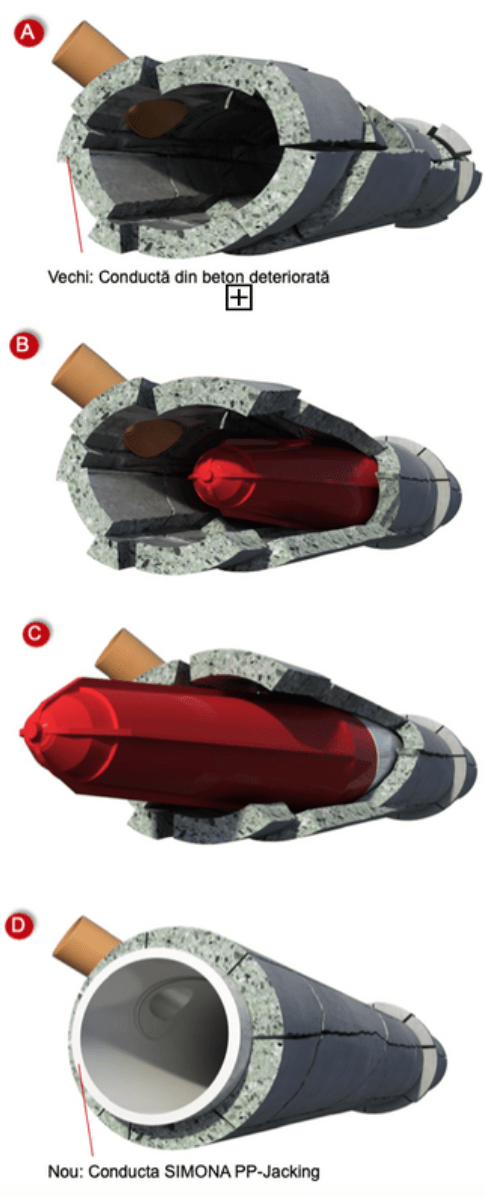

✅ Static bursting of the damaged pipe

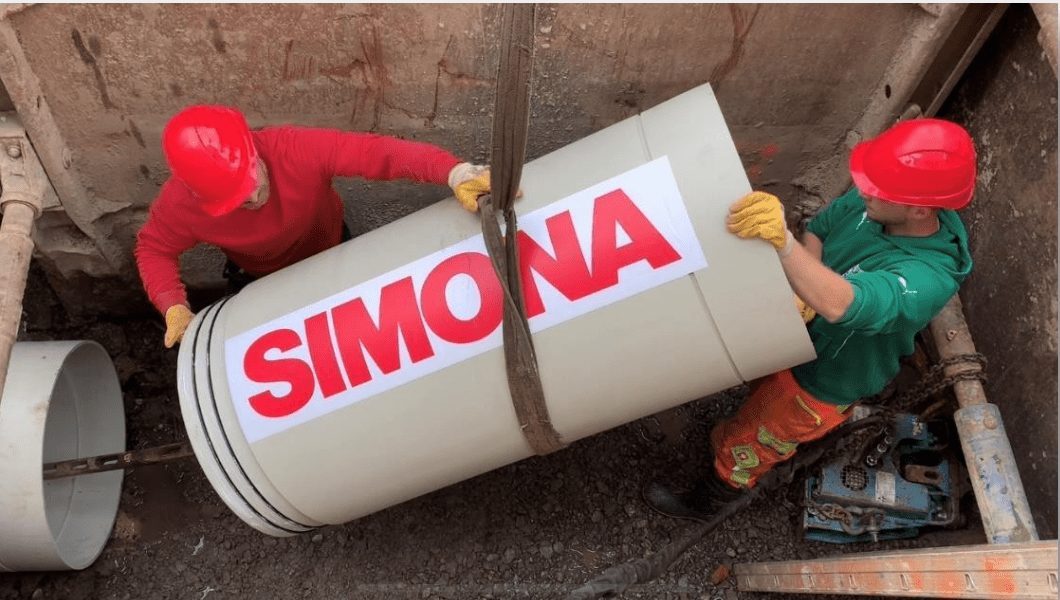

✅ Introduction of PP-H AlphaPlus® pipe modules made of homopolymer polypropylene (SIMONA patented technology)

✅ Pipes with integrated connection system, with tensile protection and double sealing gasket (made of EPDM).

This solution provides:

🔹 A watertight pipe with improved hydraulic performance

🔹 Increased wastewater transportation capacity

🔹 Reduced risk of blockages

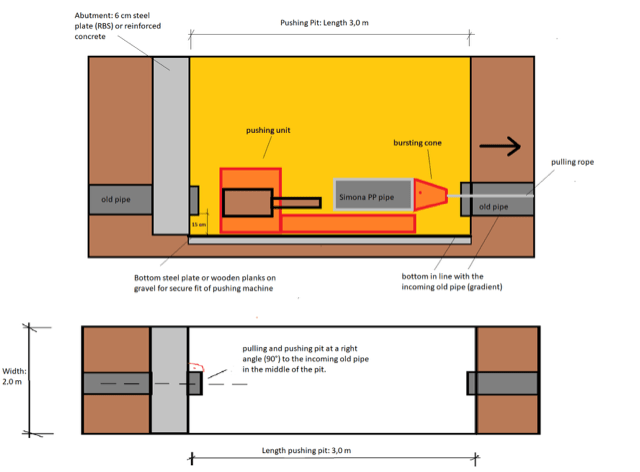

State-of-the-art equipment offering a combined force of over 200 tons for fast and accurate installation of new pipelines:

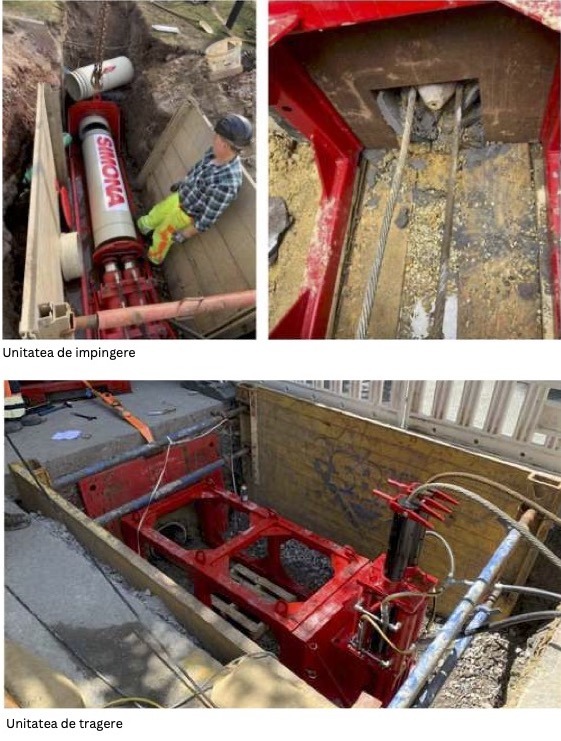

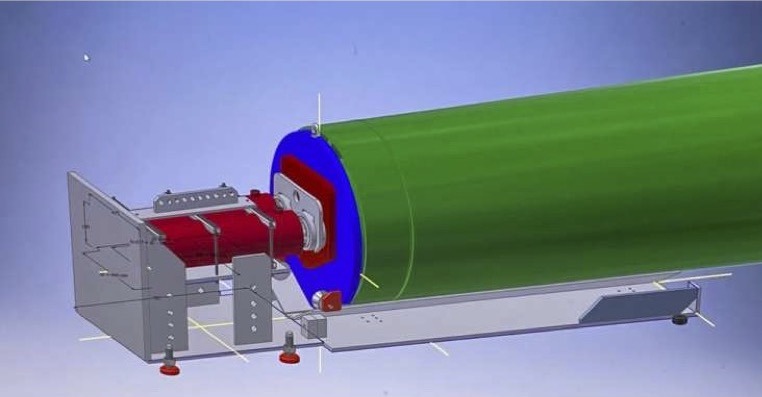

✅ RBS 1250 Winch-Burster – pulling unit (1250 KN force)

✅ RBS 880/440 – pushing unit (force up to 880 KN)

High performance materials

🔹 PP-H AlphaPlus® (SIMONA) pipes – high strength, superior watertightness and improved hydraulic performance

🔹 1.1 m modules, ideal for areas with restricted access.

The work was carried out between the launch pits of the two RBS units over a length of 40 m.

The challenges encountered during the rehabilitation were significant, including unknown conditions at the start of the work, such as massive concrete and backfilling with construction waste around the old pipeline, which generated high frictional forces. However, the equipment operated efficiently under continuous load, demonstrating its reliability.

Execution time:

✅ 2 days – preparing the pits

✅ 1 day – pipe pulling

🔹 Fast and efficient completion with minimal inconvenience to the community

RBS EQUIPMENTS

State-of-the-art technology for trenchless rehabilitation of sewage networks through controlled and efficient demolition/bursting of damaged concrete, clay or PVC pipes and fast and precise installation of innovative polypropylene (PP) pipes: the RBS 1250 Winch-Burster (Static Breaking & Pulling Unit) and the RBS 880/440 (Pushing Unit).

RBS is the only manufacturer in the world to offer the greatest flexibility for fast and efficient trenchless construction, combining pipe bursting, pushing and pulling technologies to suit the needs of the project.

BENEFITS

- Maximum possible forces for bursting old pipes using the pulling equipment and the pushing unit: more than 2000 KN for work in small pit

- 1250 KN pulling force

- Up to 880 KN additional pushing force

- Compact dimensions for small pits

- One-man operation with remote control

- Recommended system for no-dig applications, e.g:

- Recommended system for no-dig applications, e.g:

- from pit to pit, static burstlining from approx. DN 200 to DN 700 (depending on soil conditions)

- TIP method from approx. DN 300 to DN 1000 mm

SIMONA Pipes: Sustainable Innovation and Exceptional Performance

SIMONA’s innovative pipelines represent an investment that offers significant long-term benefits: low operating and maintenance costs, optimum hydraulic efficiency and exceptional service life. By incorporating special nucleating agents and fine-tuning key elements in the technological process, SIMONA has developed a unique, patented technology: SIMONA® PP-H AlphaPlus® – homopolymeric polypropylene, PP-H, with an extremely fine crystalline structure and stable α-characteristics. SIMONA is the only manufacturer of pipes and fittings to have obtained approval from DIBt (German Institute of Building Technology in Berlin) for a PP-H raw material. Simona pipes are heat-treated for improved dimensional stability and increased lifting forces.

INFORMATION about the type of pipes used in this project:

- Damaged pipe: Inside diameter 500 mm, concrete, high wear, clogged

- Innovative pipe: SIMONA PP-HM RM SV (inner diameter 500 mm), with integrated connection with tensile protection and double EPDM wedge seal.

- Short pipe modules (1.1 m) to allow easy, manual handling on site without the need for lifting equipment.

- Length section rehabilitated: 40 m

BENEFITS OF SIMONA® PP RM-SV PIPES

- Increased strength and improved ring stiffness

- Improved hydraulic performance

- Extended service life

- Versatility and reliability

- High mechanical load capacity

- Excellent chemical resistance

- High tear resistance

- Easy to handle on site without lifting equipment

- Simple and safe installation in confined spaces

- Root impact resistance

ADVANTAGES OF PP-H ALPHA PLUS TEHNOLOGY

- Improved hydraulic properties due to reduced surface roughness. The fine crystalline structure of SIMONA® PP-H AlphaPlus® contributes directly to the reduction of surface roughness inside the pipe. The surface roughness of less than 0.4 μm is a significant advantage compared to other PP-H grades, particularly at larger diameters.

- Pressure loss reduction by more than 10%

- Significant energy savings

- Cost-effective operation of piping systems

- Due to the extremely low surface roughness, these pipes are less prone to deposits and biofilm.

- Reduced risk of fouling: The smooth surface reduces biofilm formation.

- Self-cleaning: Lower operating and maintenance costs.

- Significantly higher stiffness and strength than other types of PP-H, offering enhanced functionality, durability and improved safety.

- Improved performance at high temperatures.

- Higher impact resistance at low temperatures: Increased durability in harsh conditions.

- Improved chemical resistance and minimal risk of stress cracking (>100 years): longer service life.

- Ideal solution for areas with limited space or difficult access.

THE PROJECT IN IMAGES

ADVANTAGES OF THE IMPLEMENTED TECHNOLOGY

✅ Operational Safety: Unlike other types of pipelines that can present significant risks of leaks at the joints, the solution used guarantees long-term leak tightness thanks to the innovative coupling system with integrated connection with tensile protection and double EPDM wedge seal, minimizing the risks of leaks.

✅ Increased Hydraulic Capacity: SIMONA’s patented innovative polypropylene pipes increase network capacity, improving wastewater management efficiency and supporting urban development.

✅ Long-Term Benefits: Reduced maintenance costs and extended infrastructure service life contribute to long-term operational efficiency. Pipelines installed have a lifespan of over 100 years.

✅ Minimal impact on traffic and residents: The solution used minimizes the impact on existing infrastructure, the environment, traffic and daily life, avoiding bottlenecks and discomfort for the local community.

✅ Efficiency and speed: Pull new pipelines in a single day

✅ Cost savings: Eliminate extensive digging

✅ Sustainability: Green technology, no unnecessary waste

A few advantages over CIPP: rehabilitation of severely damaged pipelines, increased hydraulic capacity of the pipelines, use of the new pipeline immediately after installation (no curing time), replacement of the pipeline with a new, high-performance pipeline, providing a durable solution.

FS Technologies and Management and its partners form a strong alliance that stands poised to revolutionize the construction and infrastructure landscape. The collaboration promises sustainable, efficient and resilient infrastructure solutions. We are at the forefront of a new era in construction, where sustainability, efficiency and innovation converge to create a better future for generations to come. Guided by our shared values and our dedication to excellence, we are paving the way to a world where construction is not just about structures, but about building a lasting legacy for the entire planet and all who call it home.

FAQ

How can I get more information about implementing NO-DIG technologies in a project?

To get more information about implementing trenchless technologies in your project, you can contact our team of specialists directly. They will provide you with detailed advice and customized solutions for your specific needs. Feel free to contact us with any questions or to set up a discussion to explore how our technology can enhance your project in a sustainable and efficient way.

📞 For expert consultancy and customized solutions, contact FS Technologies:

📩 office@fs-tech.ro | ☎️ 0747.971.855 | 🌐 www.fs-tech.ro