THE PURPOSE

To increase the hydraulic capacity of the pipeline, demonstrating the effectiveness of innovative wastewater pipeline rehabilitation technology.

Pilot Project: Rehabilitation and Sewage Pipe Diameter Extension with „pipe – bursting” technology

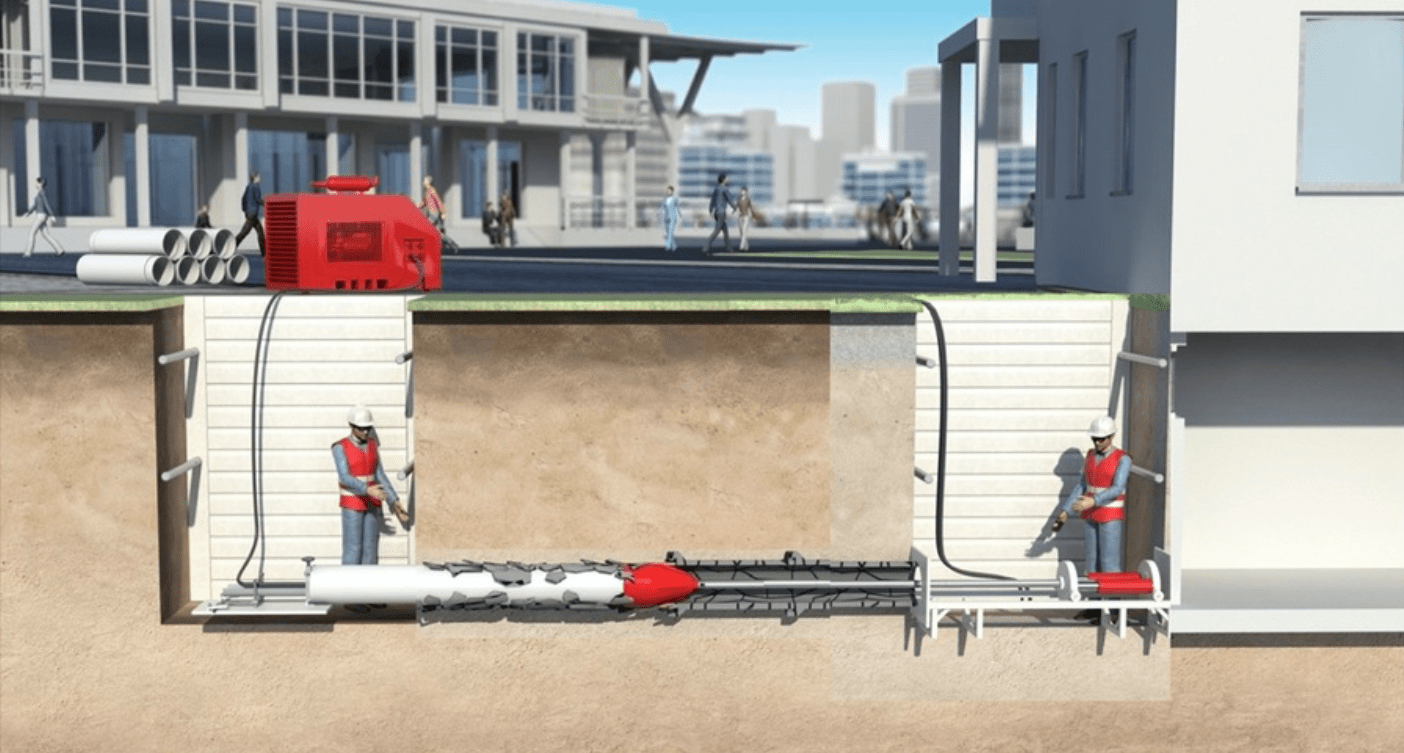

In order to rehabilitate the DN300 wastewater pipeline in the shortest possible time and with minimal disruption to traffic and the community, FS Technologies, together with Energoproiect (designer and expert), and specialists from Tracto Technik GmbH (manufacturer of pipe bursting equipment) and SIMONA AG (manufacturer of complete high- performance pipe systems and fittings) implemented an innovative solution.

The pilot project also had a demonstration, technology transfer role, with over 70 people (designers, technical experts, consultants and contractors) in attendance.

In addition to ensuring the long-term sustainability of vital infrastructure, important elements in the choice of this solution were: environmental impact, comfort of residents, limiting disruption to residents’ access to parking.

OBJECTIVES

FEASIBILITY: Demonstrate the feasibility of the static pipe bursting method for wastewater pipeline rehabilitation – without excavation.

BENEFITS: Highlight the benefits of pipebursting trenchless technology, in reducing urban disturbance.

EVALUATION: Evaluate the technical performance of the static pipe bursting method, i.e. resizing the pipe network – trenchless.

TECHNICAL SOLUTION

Expansion of sewage pipeline diameter using pipe bursting technology

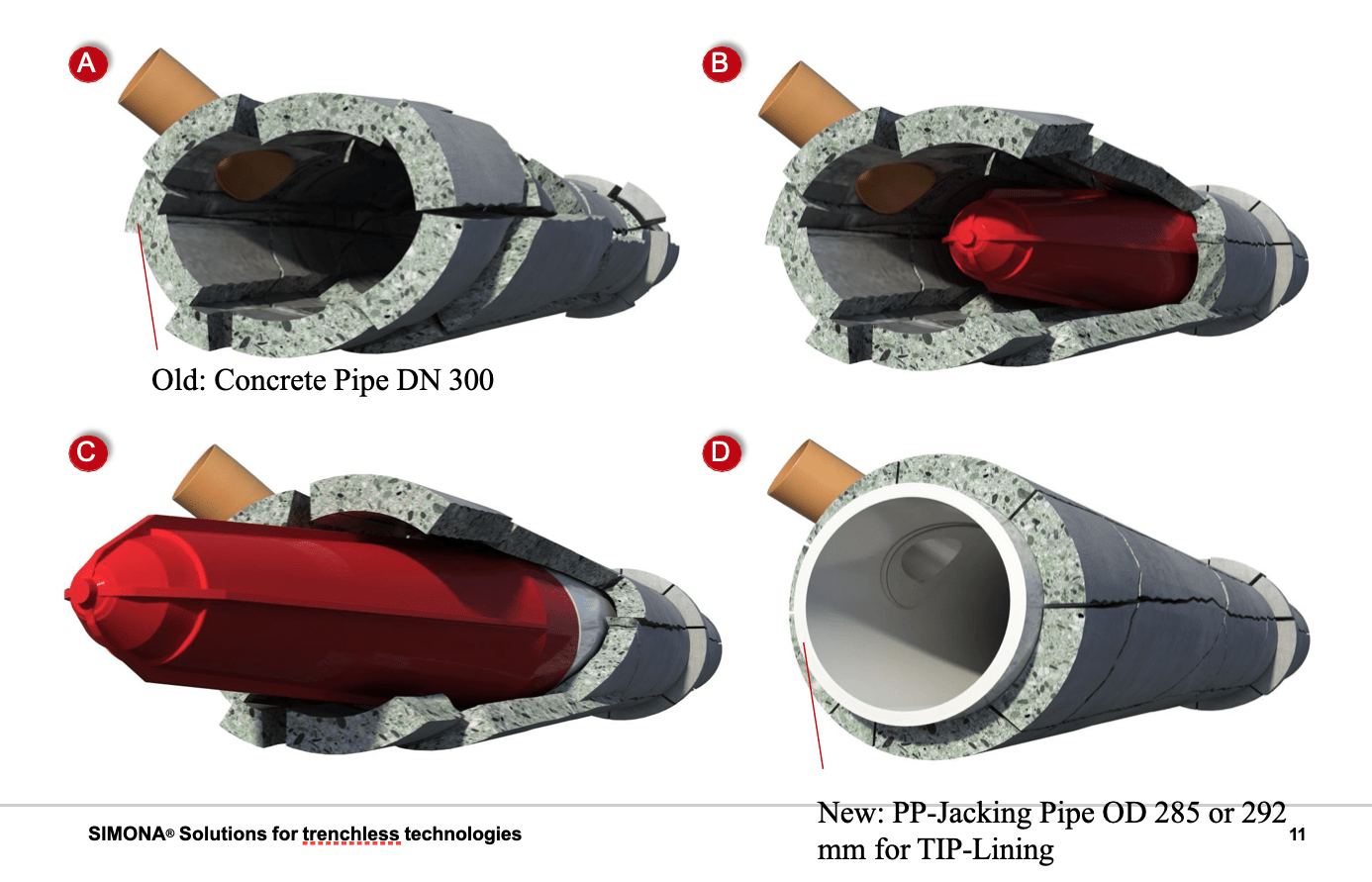

Rehabilitation of the pipeline by static bursting of the old concrete pipeline (DN 300) using the Grundoburst 800 system and trenchless installation of a new Simona PP-RSV pipe OD 392 x 18.0 mm, larger diameter – in order to increase the hydraulic capacity, DN 356 mm. Work was carried out from pit to pit, the installation length being 21 m, using pipe modules of 1.0 m length each.

- Grundoburst equipment: Using the Grundoburst system, Tracto Technik statically fractured old existing pipes and installed new pipes on site, eliminating the need for traditional excavation, minimizing environmental impact. This enabled a very fast, accurate and efficient rehabilitation of a section of pipeline in a confined urban area.

- Jacking pipes with integrated connection, SIMONA PP-RM SV, tensile protection and double EPDM wedge seal, DN 356 mm. These PP-H polypropylene pipes have been used for their superior durability, corrosion resistance and service life and are ideal for trenchless installation in urban environments. Due to their lightweight design, flexibility and small size, they were easily and safely inserted into narrow spaces in old sewers using Grundoburst 800.

Preparing the site for equipment installation:

- Construction of 2 access pits and securing their sides:

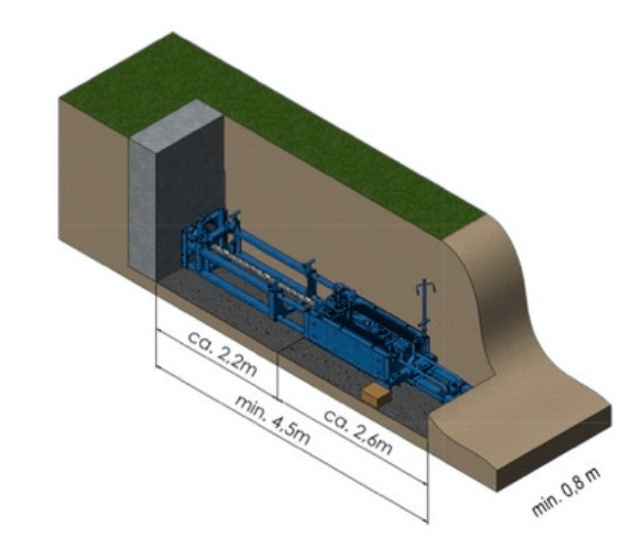

- Grundoburst launch pit: Dimensions: 5 m x 1.5 m. A thrust support was made – 30×20 cm steel brackets positioned 50 cm deeper than ground level at the base of the pit. The equipment was positioned on the right side of the pit, centred on the axis of the pipe.

- Simona pipe laying and pulling pit. Dimensions: 2 m x 1.5 m.

- Ensuring machine stability: Placing wood under the equipment to facilitate lifting.

- Due to the fact that Grundoburst 800 operates with a force of 80 tons, we have secured the manhole by armouring the walls using 2 L-profiles – metal plate, 1.5 x 2.5 m.

GRUNDOBURST: STATIC PIPE BURSTING

Transforming urban infrastructure with trenchless Tracto technology

The powerful and robust GRUNDOBURST breakers are perfectly suited for the renewal of pipes with diameters up to Ø 1,200 mm, with circular or ovoid profiles. To do this, the forklift first pushes the bursting rod through the old pipe. After the cutting tool and the new pipe have been connected, the retraction begins. The specially developed QuickLock breaker rod is not screwed in, but is quickly and efficiently fixed in place, ensuring pushing force and tensile strength. This makes handling on site considerably easier and makes it possible to tackle even slight bends. In addition to complete renewal, the versatile GRUNDOBURST systems with specific fittings can also be used for pipe repair and rehabilitation.

Using GRUNDOBURST hydraulically operated systems the old pipe is replaced with a new pipe of the same or larger diameter on the existing route. With the static bursting method, work can be carried out horizontally in both directions from the machine’s starting point.

Grundoburst video: here

- Minimal disruption:

- By using trenchless technology, GRUNDOBURST equipment minimises damage to communities and the natural environment. Projects can be completed with less digging, preserving green spaces and mature trees, and minimizing inconvenience to residents and businesses.

- Efficient installation:

- The innovative design of the GRUNDOBURST equipment allows for fast and efficient installation of new pipes. Thanks to quick rod insertion and removal, as well as fast operating cycles, projects can be completed promptly, reducing downtime and minimizing disruption to surrounding areas.

- Versatility:

- GRUNDOBURST equipment is versatile and can be used for a wide range of pipeline renovation projects. Whether replacing old sewer pipes or installing new water pipes, the equipment’s compact size and high performance make it suitable for various applications.

- Environmental protection:

- By minimising excavation and preserving natural habitats, GRUNDOBURST equipment helps to protect the environment. Communities can enjoy a cleaner and healthier environment, while businesses benefit from better environmental management and public perception.

GRUNDOBURST ADVANTAGES

SIMONA PP-HM RM SV

SIMONA Pipes: Sustainable Innovation and Exceptional Performance

SIMONA pipelines represent a wise investment that offers significant long-term benefits: low operating and maintenance costs, optimum hydraulic efficiency and an exceptional service life.

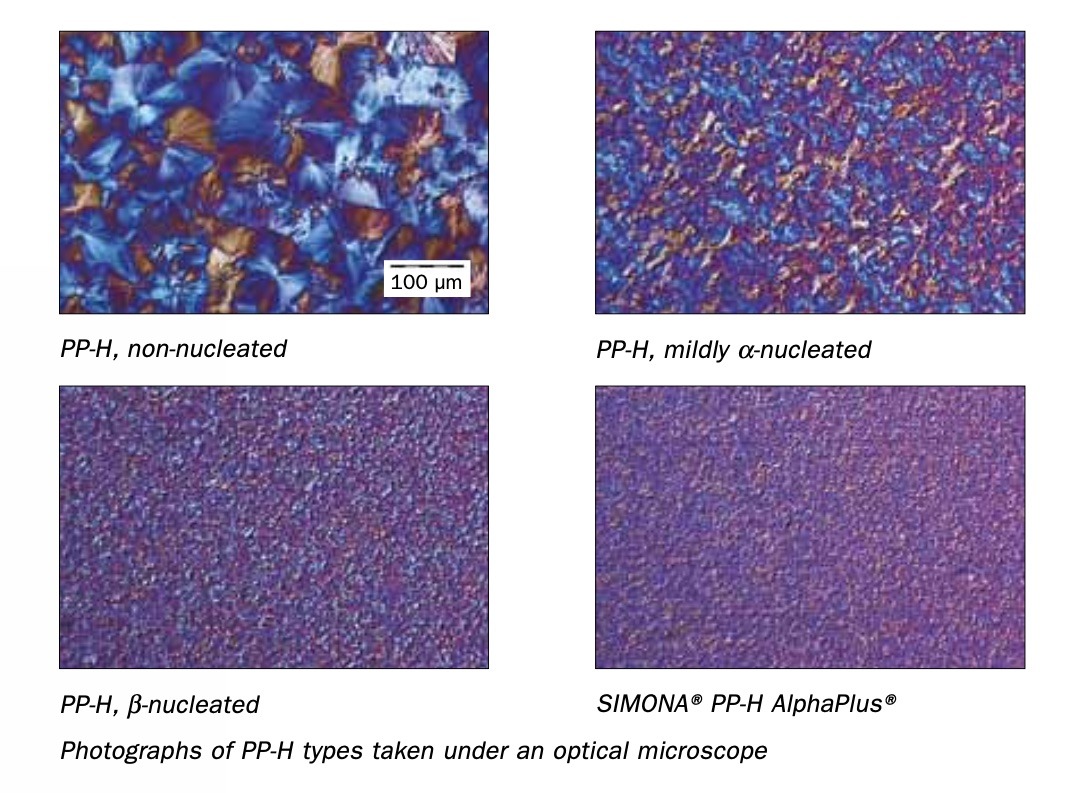

By incorporating special nucleating agents and adjusting key elements of the engineering process, SIMONA has developed a unique, patented technology: SIMONA® PP-H AlphaPlus® – homopolymeric polypropylene, PP-H, with an extremely fine crystalline structure and stable 3 characteristics. SIMONA is the only manufacturer of pipes and fittings to have obtained approval from the DIBt (German Institute for Building Technology in Berlin) for a PP-H raw material. Simona pipes are heat-treated for better dimensional stability and increased lifting forces.

INFORMATION about the type of pipelines used in this project:

- Old pipeline: Diameter 300mm, concrete, cracked, degree of clogging – average age.

- New pipeline: SIMONA PP-HM RM SV (diameter 358 mm), with integrated connection with tensile protection and double EPDM wedge seal.

- Length of rehabilitated section: 21 m

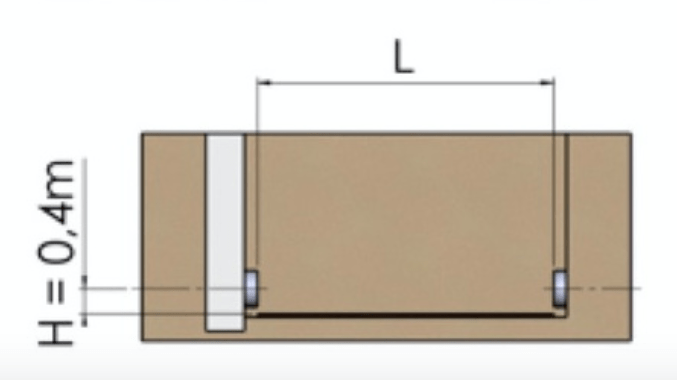

- Short pipe modules (1m) to allow easy manual handling on site without the need for lifting equipment

- Improved hydraulic properties due to reduced surface roughness. The fine crystalline structure of SIMONA® PP-H AlphaPlus® contributes directly to the reduction of surface roughness inside the pipe. The surface roughness of less than 0.4 μm is a significant advantage compared to other PP-H types, especially at larger diameters.

- Reduction of pressure losses by more than 10%.

- Significant energy savings

- Cost-effective operation of piping systems

- Due to the extremely low surface roughness, these pipes are less prone to deposits and biofilm.

- Reduced risk of fouling: The smooth surface reduces biofilm formation.

- Self-cleaning: Lower operating and maintenance costs

- Significantly higher stiffness and strength than other types of PP-H, providing increased functionality, durability and improved safety.

- Improved high temperature performance.

- Higher impact strength at low temperatures: Increased durability in harsh conditions.

- Improved chemical resistance and minimal risk of stress cracking (>100 years): longer lifetime

- Year-round rehabilitation of sewerage networks (wastewater, municipal).

- Ideal solution for areas with limited space or difficult access.

ADVANTAGES SIMONA PP-HM RM SV PIPES

CONCLUSION

The technology implemented in this pilot project represents a viable solution for trenchless pipe bursting rehabilitation, offering a number of significant advantages. With careful planning and proper execution, this solution can help upgrade aging pipelines and increase their capacity, while minimizing disruption to the crowded urban environment.

ADVANTAGES OF THE SYSTEM USED IN THIS PILOT PROJECT

Extension of the diameter of the sewage pipeline using pipe bursting technology

- Efficiency and Durability: Fast execution reduces downtime for regular activities. The use of durable, corrosion-resistant piping ensures extended infrastructure life. Increased capacity ensures adaptation to the growing needs of cities and further infrastructure development.

- Long-term benefits: Reduced maintenance costs, extended infrastructure life and increased operational efficiency

- Reduced Urban Impact: Eliminating the need for extensive excavation reduces disruption and destruction of urban infrastructure, helping to preserve and protect the surrounding urban environment and townscape.

- Minimal Disruption: Ensures uninterrupted traffic flow and minimizes inconvenience to residents and businesses by avoiding road jams and work zone disruptions, resulting in reduced stress and discomfort in the community.

Some advantages over CIPP: rehabilitation of severely damaged pipelines, increased hydraulic capacity of the pipeline, use of the new pipeline immediately after installation (no curing time), replacement of the pipeline with a new one, performance, providing a sustainable solution.

FS Technologies, SIMONA and Tracto together form a powerful alliance poised to revolutionise the construction and infrastructure landscape. With FS Technologies bringing expertise and efficiency, Simona providing high-quality thermoplastic solutions, and Tracto being a pioneer of trenchless technology, the collaboration promises sustainable, efficient and resilient infrastructure solutions. We are at the forefront of a new phase in construction, where sustainability, efficiency and innovation converge to create a better future for generations to come. Guided by our shared values and our dedication to excellence, we are leading the way to a world where building is not just about structures, but about building a lasting legacy for the whole planet and all who call it home.

FAQ

How can I get more information about implementing Tracto trenchless technology in a project?

For more information about implementing Tracto trenchless technology in your project, you can contact our team of specialists directly. They will provide you with detailed advice and customised solutions for your specific needs. Feel free to contact us with any questions or to set up a discussion to explore how our technology can improve your project in a sustainable and efficient way. Contact: office@fs-tech.ro