Infrastructure: Global challenges

As the world’s population continues to grow, especially in urban areas, the pressure on infrastructure is becoming increasingly evident. Urbanization leads to greater demand for public utilities such as water, sanitation, and transport, putting pressure on existing systems.

Many cities around the world are struggling with ageing infrastructure, including sewage systems, water pipes,, and water transport networks. These ageing systems are prone to breakdowns, leaks, and malfunctions, posing risks to public health, safety, and the environment.

Case Study: Danson Park Rehabilitation

Sustainable Urban Growth with Tracto Trenchless Technology

Danson Park, located in the heart of bustling South London, is a quiet haven for residents and visitors alike. With its extensive green spaces, picturesque lake, and historic Palladian mansion, the park has been a treasured retreat for centuries. Despite its tranquil surroundings, Danson Park requires ongoing maintenance and modernization to continue to effectively serve the surrounding communities. A key aspect of this modernization effort has been the renovation of the aging sewer line that runs underneath the park.

In the summer of 2023, Thames Water embarked on a mission to upgrade the ageing sewer pipe that runs through Danson Park. The project aimed to replace the old clay pipe with a larger, more efficient polyethylene pipe to improve sewer flow and reduce the risk of blockages. Replacing the aging pipeline presented several challenges, including minimizing disruption to park visitors and preserving the natural beauty of the park. Thames Water sought innovative solutions to address these challenges while ensuring the success of the project. Cappagh Construction Ltd., a leader in trenchless installation methods, proposed an innovative solution to minimise disruption during the pipeline refurbishment project. Instead of traditional excavation methods, Cappagh recommended using trenchless techniques to install the new pipeline.

Operation of GRUNDOBURST equipment

The trenchless method used by Cappagh involved static bursting, which allowed the old pipe to be dislodged and a larger polyethylene pipe to be installed along the same route. This approach eliminated the need for extensive excavation, thus protecting the park’s landscape and minimising visitor disturbance.

To efficiently execute the trenchless rehabilitation project, Cappagh Construction partnered with Tracto UK to purchase the GRUNDOBURST 800G equipment. This high-performance equipment provided the traction needed to expand the pipeline efficiently while minimizing surface damage.

GRUNDOBURST: STATIC PIPE BURSTING

Transforming urban infrastructure with trenchless Tracto technology

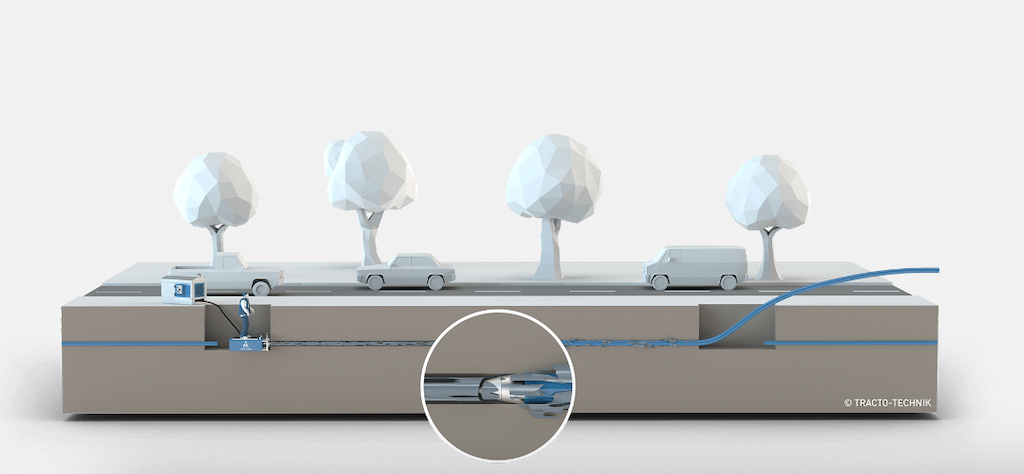

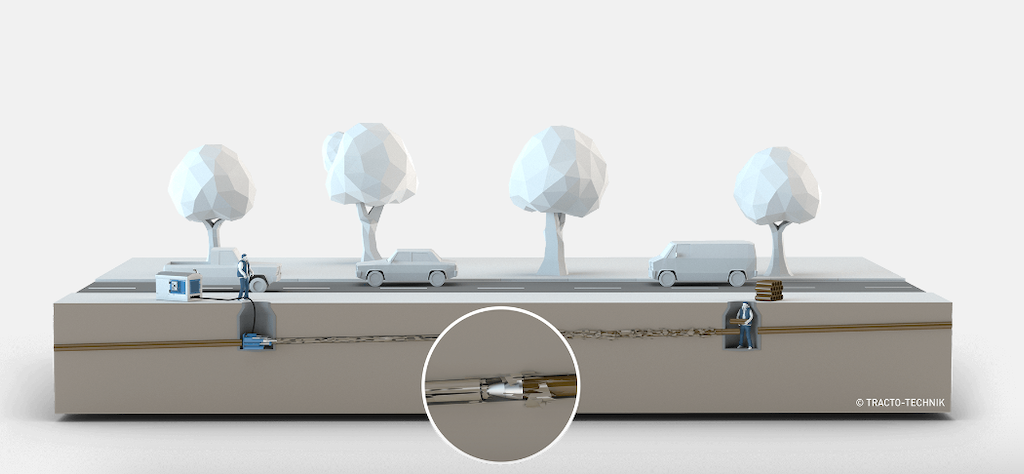

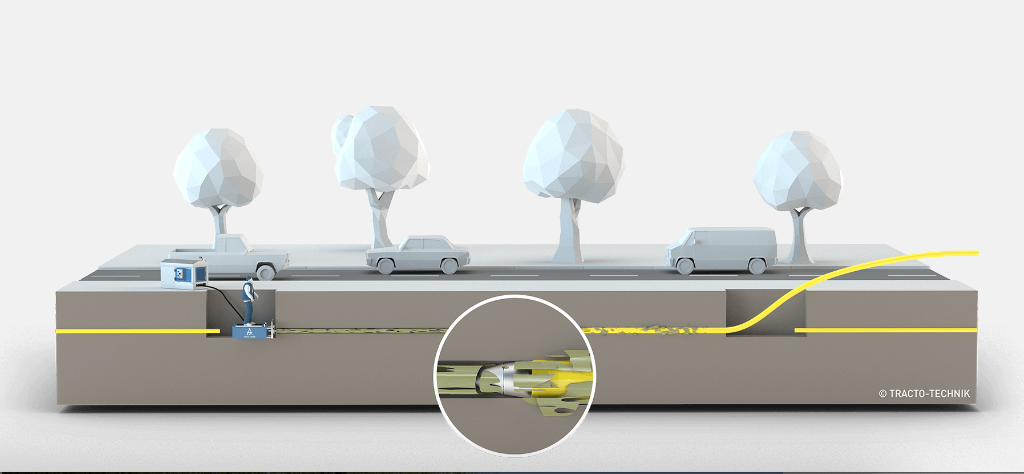

The powerful and robust GRUNDOBURST breakers are perfectly suited for the renewal of pipes with diameters up to Ø 1,200 mm, with circular or ovoid profiles. To do this, the forklift first pushes the bursting rod through the old pipe. After the cutting tool and the new pipe have been connected, the retraction begins. The specially developed QuickLock breaker rod is not screwed in, but is quickly and efficiently fixed in place, ensuring pushing force and tensile strength. This makes handling on site considerably easier and makes it possible to tackle even slight bends. In addition to complete renewal, the versatile GRUNDOBURST systems with specific fittings can also be used for pipe repair and rehabilitation.

Using GRUNDOBURST hydraulically operated systems the old pipe is replaced with a new pipe of the same or larger diameter on the existing route. With the static bursting method, work can be carried out horizontally in both directions from the machine’s starting point.

Sustainable renewal

Static pipe bursting makes it possible to create a completely new pipeline with a lifespan of 80–100 years. With GRUNDO-BURST, damaged pipes can be renewed on their existing route.

A powerful optimizer

Five powerful models with tensile forces ranging from 400 to 2,500 kN allow the renewal of pipes up to Ø 1,200 mm. By introducing new pipes with smaller or larger diameters, the pipe capacity can be adjusted during renewal.

Perfect connection

QuickLock breakout rods are very strong, durable, and insensitive to dirt. Thanks to the quick-lock coupling, without screwing, removal and insertion are faster. The connection is stretch- and shear-resistant and adaptable to bends.

Controlled strengths

In addition to the classic bursting method (new pipe of equal or larger Ø), GRUNDOBURST systems can also be used for partial repair and rehabilitation of pipes. Suitable fittings allow the repair of long and short pipes, bursting for calibration, TIP (tight-in-pipe) sealing, and the reduction method.

Multi-purpose flexible

Since pipes should not be overloaded when pulled in, the tensile forces acting must be checked and recorded. This is done safely and reliably by GRUNDOLOG tensile force measuring devices for performance classes 150 kN, 400 kN, 1,250 kN, and 2,500 kN.

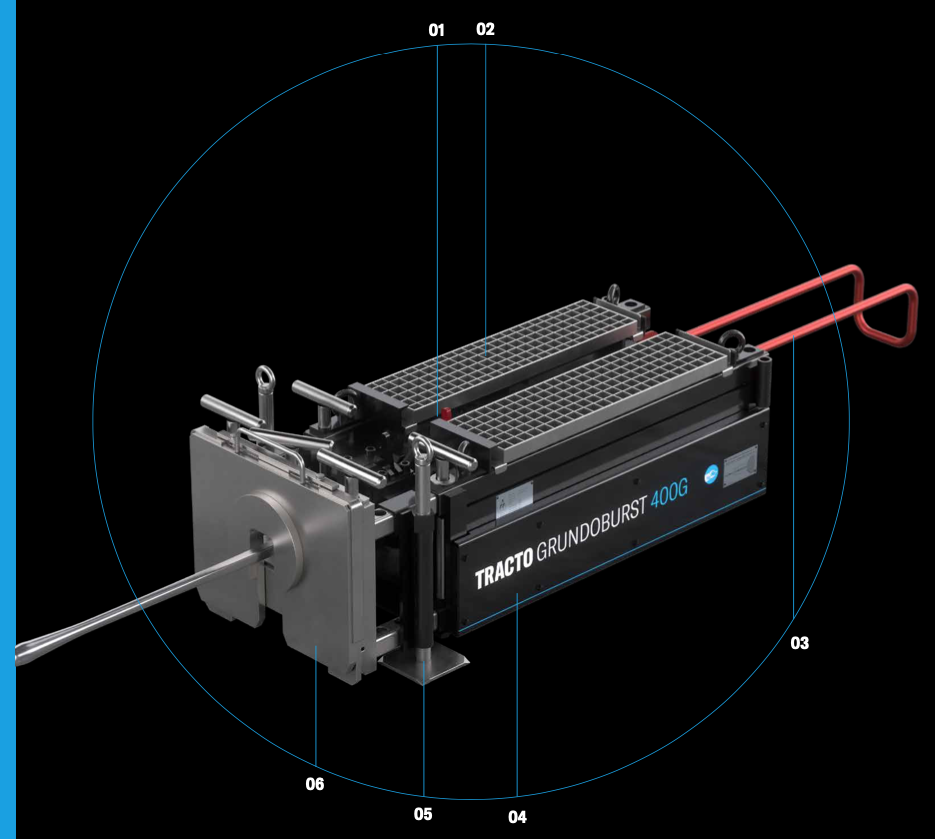

- 01: Two locking devices prevent the rods from sliding back

- 02: Steps for safe standing

- 03: Safety bracket in the exit area of the blasting rod

- 04: Very simple and robust frame design

- 05: Height adjustment via threaded rods

- 06: Integrated telescopic extension frame

Application type for sustainable urban development with Tracto trenchless technology

Water transport pipes

Sewerage

Gas distribution

- Minimal disruption:

- By using trenchless technology, GRUNDOBURST equipment minimises damage to communities and the natural environment. Projects can be completed with less digging, preserving green spaces and mature trees, and minimizing inconvenience to residents and businesses.

- Efficient installation:

- The innovative design of the GRUNDOBURST equipment allows for fast and efficient installation of new pipes. Thanks to quick rod insertion and removal, as well as fast operating cycles, projects can be completed promptly, reducing downtime and minimizing disruption to surrounding areas.

- Versatility:

- GRUNDOBURST equipment is versatile and can be used for a wide range of pipeline renovation projects. Whether replacing old sewer pipes or installing new water pipes, the equipment’s compact size and high performance make it suitable for various applications.

- Environmental protection:

- By minimising excavation and preserving natural habitats, GRUNDOBURST equipment helps to protect the environment. Communities can enjoy a cleaner and healthier environment, while businesses benefit from better environmental management and public perception.

GRUNDOBURST advantages

The importance of trenchless technology worldwide

Trenchless technology offers sustainable solutions to infrastructure challenges around the world, from replacing aging pipelines to installing new water and sewer pipes. Its versatility and minimal environmental impact make it an attractive option for cities facing the need for infrastructure upgrades.

The implementation of trenchless technology plays a key role in promoting sustainable urban development by reducing environmental disruption, conserving natural resources, and improving infrastructure resilience. By minimising surface disturbance and preserving green spaces, trenchless solutions contribute to healthier and more liveable cities.

The future of

trenchless

technologies in

Romania

Foto: Adrian Dascal

Romania faces significant challenges related to aging infrastructure and environmental conservation. The need to modernise infrastructure while protecting natural habitats and cultural heritage sites should be an urgent concern for the Romanian authorities.

Trenchless technology, such as TRACTO’s GRUNDOBURST series, holds great promise for addressing Romania’s infrastructure challenges. By minimising excavation and surface disturbance, trenchless solutions offer a sustainable approach to infrastructure upgrading while ensuring the comfort of congested urban communities and avoiding massive and prolonged traffic disruption while preserving Romania’s rich natural and cultural heritage.

The power of trenchless technology

Building sustainable communities

The Danson Park sewer line renovation is a demonstration of the transformative power of trenchless technology in upgrading essential infrastructure while preserving natural beauty. By adopting innovative solutions and sustainable practices, communities can build resilient infrastructure that meets the needs of current and future generations.

Looking towards the future

As cities around the world continue to face infrastructure challenges, trenchless technology will play an increasingly important role in creating sustainable and livable communities. Sustainable Urban Growth with Tracto Trenchless Technology.

Imagini & video: Tracto

FAQ

How can I get more information about implementing Tracto trenchless technology in a project?

For more information about implementing Tracto trenchless technology in your project, you can contact our team of specialists directly. They will provide you with detailed advice and customised solutions for your specific needs. Feel free to contact us with any questions or to set up a discussion to explore how our technology can improve your project in a sustainable and efficient way. Contact: office@fs-tech.ro

FS Technologies, Simona and Tracto together form a powerful alliance poised to revolutionise the construction and infrastructure landscape. With FS Technologies bringing expertise and efficiency, Simona providing high-quality thermoplastic solutions, and Tracto being a pioneer of trenchless technology, the collaboration promises sustainable, efficient and resilient infrastructure solutions. We are at the forefront of a new phase in construction, where sustainability, efficiency and innovation converge to create a better future for generations to come. Guided by our shared values and our dedication to excellence, we are leading the way to a world where building is not just about structures, but about building a lasting legacy for the whole planet and all who call it home.